As one of the core three-electric systems of pure electric commercial vehicles, the power battery pack mainly provides power for drive. It is not only expensive, but also related to the mileage. For power batteries, temperature is one of the key factors affecting the normal charging and discharging performance and cruising range of the battery. Overheating may affect the heat dissipation of the battery and even cause spontaneous combustion. Overcooling will cause a significant reduction in vehicle range, damage the battery, and reduce the battery's performance and service life. Therefore, electric vehicles are equipped with a battery thermal management system.

So what is the role of the battery thermal management system? What are the mainstream battery thermal management systems?

In addition to dissipating heat for the battery pack, some will also heat the battery pack so that the battery can quickly enter the best working state in a low temperature environment. Liquid cooling has a higher and stronger heat dissipation efficiency than air cooling. When facing heavy loads or high-power output batteries with excessive power load, the liquid cooling water circulation heat dissipation system can cool the battery pack in time. The battery temperature can be more efficiently controlled within a reasonable range, so that the battery pack can be further improved in terms of work efficiency, stability and durability, and effectively improve the stability and service life of the battery pack. However, the liquid cooling thermal management solution has a higher purchase cost and a more complex overall design.

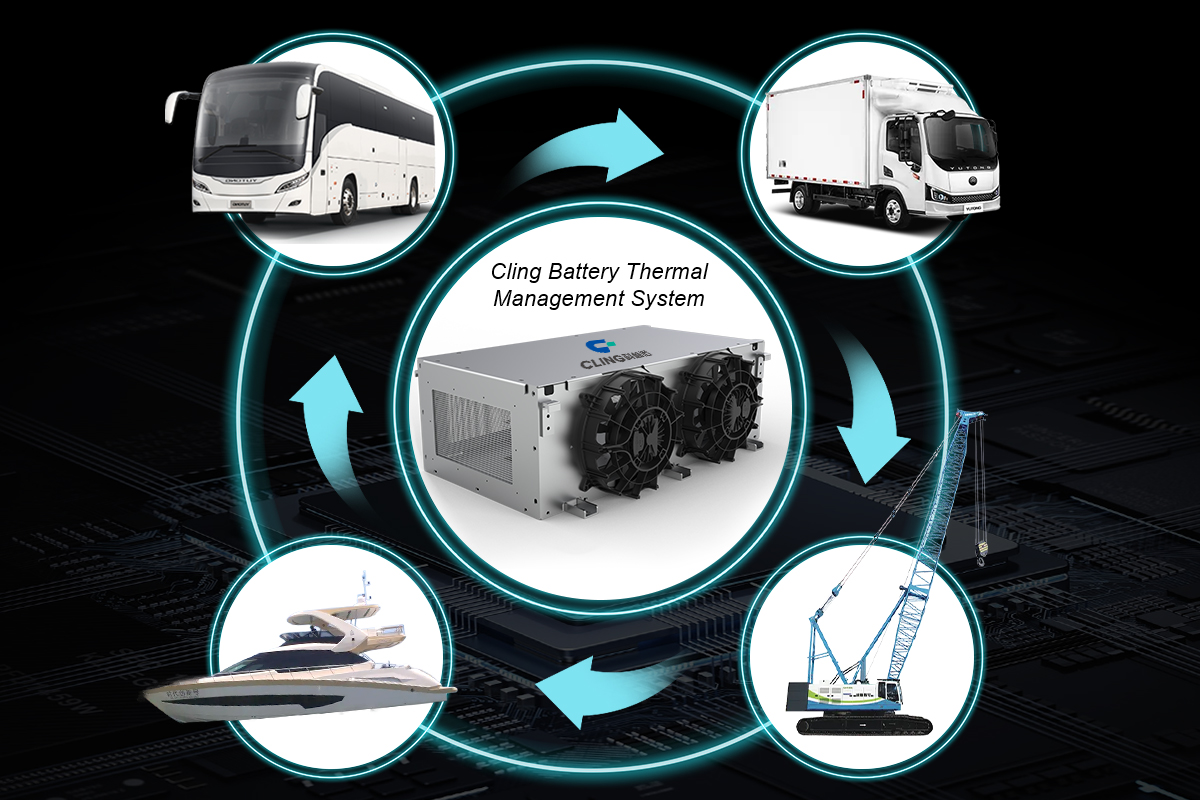

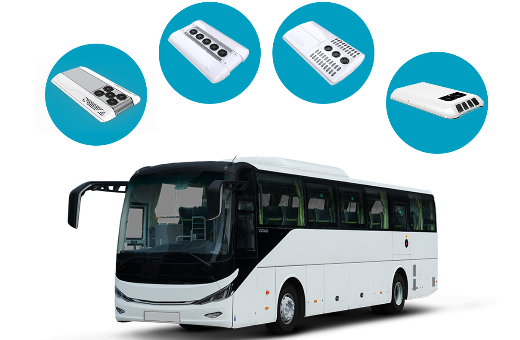

As a professional electric bus air conditioner manufacturer in China, Molead Cling bus HVAC offers battery thermal management system with shortest leadtime possible! 20 years professional experience and reputation guarantees the extraordinary performance!

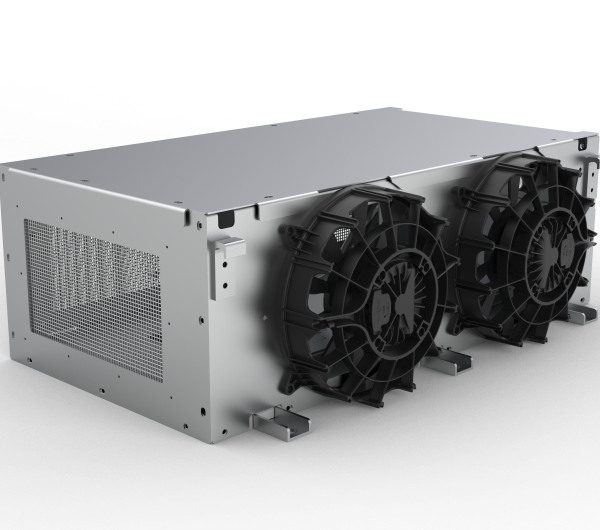

Cling EDDR Series Independent Battery Thermal Management System (BTMS)

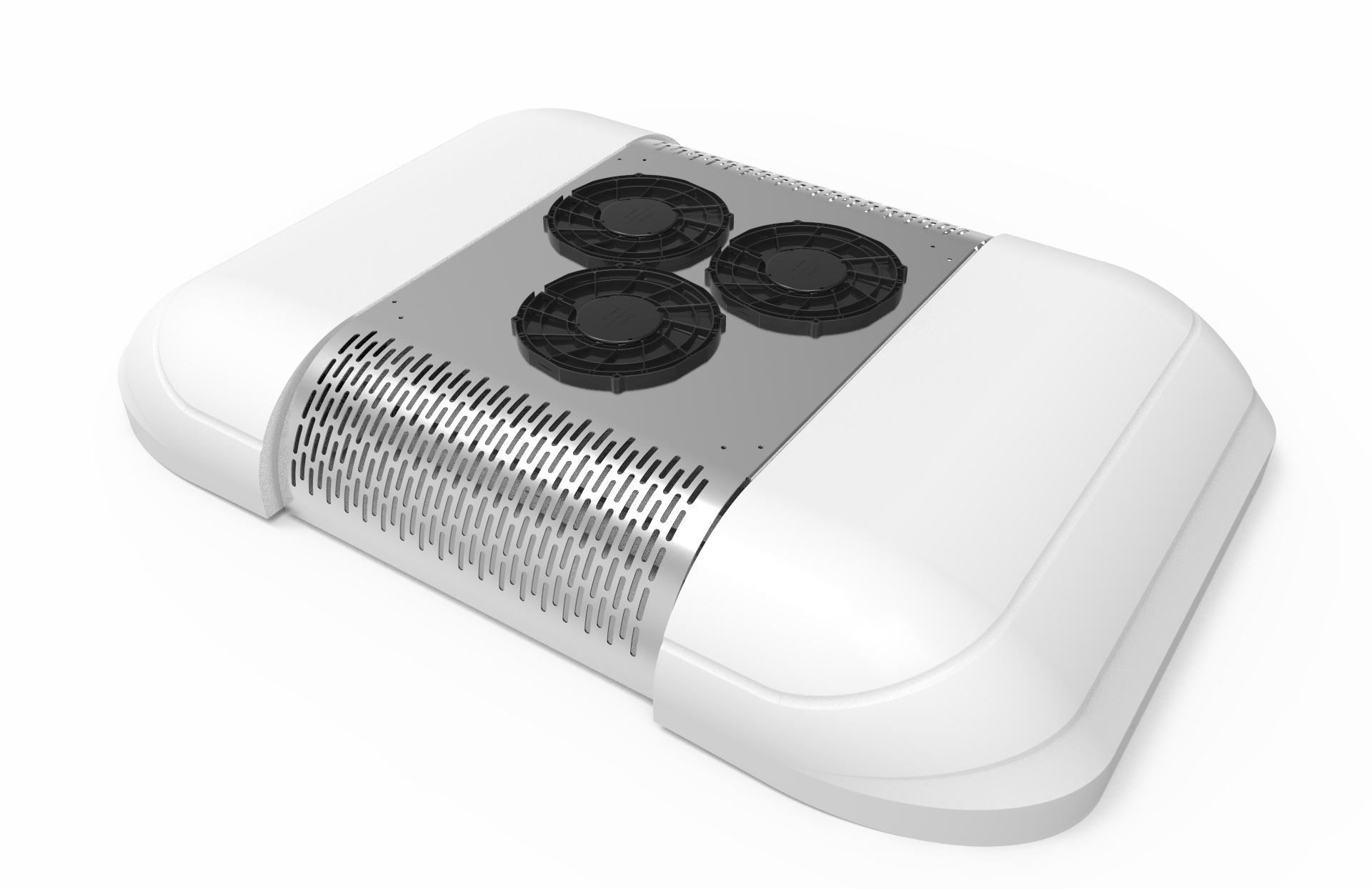

Cling EFDR Series Independent Battery Thermal Management System

If you are interested in our products please don't hesitate to contact us.

China

China English

English French

French Spanish

Spanish Russian

Russian